FABRICANT PROPULSION NAVALE POUR UNITES JUSQU’A 90 METRES

Spécialiste propulsion, fabrication hélices et lignes arbres porte-hélices complètes

Consultant

PROPULSION NAVALE PAR HELICES

Plus qu’un fabricant et réparateur de systèmes de propulsion marine, FRANCE HELICES vous conseille dès les premiers plans de votre navire monocoque et multicoque pour la fabrication d’hélices, lignes d’arbres porte hélices complètes et drives de surface SDS.

FABRICATION

PROPULSION NAVALE PAR HELICES

FRANCE HELICES développe, calcule, et fabrique des ensembles complets de propulsion pour votre bateau (ligne d’arbre porte hélice, hélice, chaise, gouvernail safran…) et systèmes de drives de surface SDS en France selon votre votre cahier des charges.

REPARATION

PROPULSION NAVALE PAR HELICES

Après un diagnostic en nos ateliers, FRANCE HELICES favorise quand cela est possible la réparation et la modification de votre propulsion.

SAV

FRANCE ET INTERNATIONAL

Afin de garantir des performances optimales dans le temps, nous vous conseillons de faire contrôler votre matériel.

Notre coeur de métier est la recherche, le développement, la fabrication, la réparation et l’usinage de systèmes de propulsion marine par hélices sur-mesure haut de gamme. Notre mission est d’apporter des solutions techniques à notre clientèle. Nos sites de fabrication FRANCE HELICES assurent l’ensemble des fabrications hélices et usinages lignes d’arbres complètes avec un service qualité présents à tous les stades de la production.

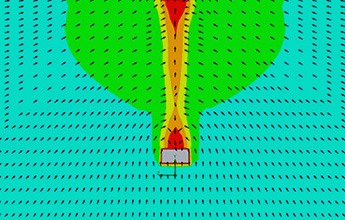

La propulsion doit être parfaitement adaptée aux caractéristiques du navire. Nous réalisons une étude technique suivant les exigences du client afin de calculer et concevoir une propulsion sur mesure (fabrication hélice et ligne arbre complète), idéale pour assurer une performance optimale (vitesse et accélération), des nuisances sonores réduites, un minimum de vibration, une économie d’énergie tout en maitrisant les phénomènes de cavitation.

votre propulsion MARINE sur-mesure

[insta-gallery id= »1″]